URSVIKEN PRESS BRAKES

Ursviken develops a complete line of highly efficient and precise press brakes for any application. Offering customized solutions that increase productivity and quality of our customer’s products.

Ursviken integrated modular systems can be customized according to user requirement. OptiFlex comes with a line of features that makes it possible to customize the machine for any manufacturing need. OptiFlex comes standard with our Angle and Springback Control device that ensures that every bend is kept within a tolerance of +/- 0.3 degrees. No other press brake can deliver this precision on a continuous basis. The angle measurer and the CNC controlled dies allow for a more versatile and faster production when it comes to more demanding projects and shorter runs. The OptiFlex press brake comes standard with extended tool space, unlimited gap frame and advanced technology prepared for automatic manufacturing, with exceptional accuracy at increased productivity speed. |

MC MACHINERY LASER | AUTOMATION | PRESS BRAKES | SHEARS | INSPECTION

MC MACHINERY has solutions for virtually every aspect of metalworking—laser cutting, EDM, milling and press brake machines—to help bring your business to the next level. So whether developing integrated manufacturing cells from the ground up, or adding specific solutions to complement existing operations VBA can provide pre-sales, sales, installation and application support staff with MC MACHINERY to help you eliminate bottlenecks, improve accuracy and drive throughput.

|

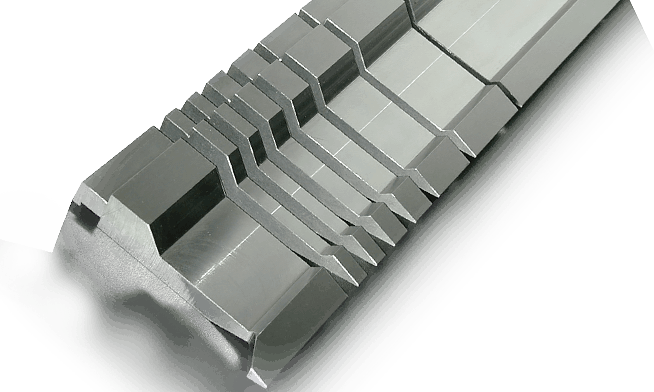

FAB SUPPLY INCORPORATED | PRESS BRAKE TOOLING

Fab Supply offers complete lines of precision ground European/Amada style, precision ground American style and Wila/Trumpf Style press brake tooling, as well as standard conventional and precision planed tooling. Special configuration profiles are available in a variety of fitting styles and quality grades to suit virtually any forming need.

FAB Supply Inc., located in Glendale Heights, IL, is the first press brake tooling company in North America to achieve ISO 9001:2000 certification. This achievement is evidence of our commitment to total customer service and satisfaction. Our unique ability to provide our customers with virtually any style and grade of tooling enables us to recommend to and furnish our customers with the best possible solution to their sheet metal forming challenges. Whether it is precision ground tooling, special configurations, conventional tools, or the revolutionary Rolla-V lower dies, FAB Supply can give you the competitive edge. With a tooling inventory of over $1.5 million and a dedicated commitment to on-time delivery of non-stock items, you can rely on FAB Supply to meet your company’s needs. |

|

YOUR TRUSTED SOURCE FOR MANUFACTURING INNOVATION

|