COSTA SANDERS DEBURRING

Metalworking Technology

Costa Sanders stands for innovation in the field of treating metal surfaces. Their product lines cover the spectrum of abrasive surface preparation. Metal applications include tolerance grinding, slag and burr removal, oxide removal, or abrasive polishing and finishing. Costa Sanders manufacture equipment to handle any level of production and any size material to be processed in a wide variety of applications. The MD series deburring and finishing machine family is Costa's solution for wet or dry process grinding, slag and burr removal, oxide removal, edge rounding, graining, and polishing. The entire MD-WD Series families are fully customizable. They can be built in different frame sizes, widths, motor power levels, and the combination of working units to best match your application requirements. |

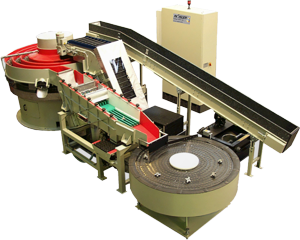

ROSLER METAL FINISHING

When it comes to dealing with surface finishing and surface preparation problems, Rösler offers the total process solution! Our customers can choose between two processing technologies, Mass finishing or Shot blasting, which offer virtually unlimited possibilities.

Rösler’s mass finishing systems are the best-selling systems in the world, thanks to their high level of innovation, cost-effectiveness and ability to significantly reduce cycle times. Significant cost reductions can be realized by using Rosler’s mass finishing systems, especially when used as a replacement for time consuming and labor intensive manual finishing processes. Rosler shot blasting systems offer you nearly unlimited options from deflashing, descaling, sanding and rust removal to roughening, matting, smoothing, edge rounding and shot peening. There are few technical applications for metal surfaces that can offer the variety of uses that shot blasting technology can offer. Finishing of mineral components such as concrete and sandstone, glass, textiles, wood and plastics is all possible with Rosler machines. Developed by Rösler, the Continuous flow installations is suited for continuous deburring, grinding, cleaning, deflashing and other surface treatment applications, all within a relatively small footprint. Every Continuous flow installation is equipped with Rosler's own High-Energy direct drive system. With Rösler you have the largest product range at your disposal. No other manufacturer can offer a comparable selection. |

|

YOUR TRUSTED SOURCE FOR MANUFACTURING INNOVATION

|